The Complexities Of Automating Nike's Sneaker Production Process

Table of Contents

Technological Hurdles in Automating Sneaker Production

Automating the creation of a Nike sneaker isn't simply a matter of replacing human workers with robots. The process is far more nuanced, demanding sophisticated technology capable of handling the inherent complexities of design and material.

The Varied Nature of Sneaker Design and Materials

Nike's product line boasts incredible diversity in design and materials. This variety presents a significant hurdle for automation. Robots designed for one type of material, like stitching leather, may not be easily adaptable to working with lightweight mesh or intricate knit fabrics.

- Difficult-to-automate materials: Leather (varying thicknesses and textures), knitted fabrics (complex weaves and stretches), TPU (thermoplastic polyurethane) components requiring precise molding.

- Challenging design elements: Intricate stitching patterns, complex layered constructions, individually placed components (like eyelets or Swooshes).

- The need for flexible robotics and AI-driven systems is paramount to overcome this heterogeneity. These systems must be able to adapt to the unique characteristics of each material and design.

Precision and Quality Control in Automated Assembly

The precision required in sneaker assembly is remarkable. Even minor inconsistencies can impact the final product's comfort, durability, and aesthetic appeal. Automating processes like stitching, gluing, and applying intricate details necessitates extremely high precision and advanced quality control measures.

- Difficult-to-automate assembly steps: Precise stitching of complex patterns, consistent application of adhesives, accurate placement of small components, ensuring uniform pressure during molding processes.

- Advanced vision systems and sensor technology are crucial for monitoring the assembly process in real-time, detecting flaws, and ensuring quality consistency. This requires sophisticated AI to interpret the visual data and make real-time adjustments.

Integration of Existing Manufacturing Processes

Integrating new automation technologies into Nike's existing global manufacturing infrastructure presents significant logistical and technological challenges. This involves overcoming compatibility issues with legacy systems, ensuring seamless data flow across different facilities, and providing comprehensive training for workers.

- Challenges in integration: Upgrading aging machinery, integrating diverse data formats from various factories, ensuring cybersecurity across a global network, training workers on new technologies and processes.

- A phased implementation approach, strategically planned across Nike's global network, is necessary for minimizing disruption and maximizing the effectiveness of automation. Careful consideration of each factory's specific needs and capabilities is critical for successful integration.

Economic and Social Considerations of Automation

The decision to automate Nike's sneaker production involves far more than just technological feasibility; it necessitates a thorough evaluation of the economic and social ramifications.

Cost of Implementation and Return on Investment (ROI)

Implementing advanced automation technologies in sneaker manufacturing is a significant financial undertaking. The investment involves substantial costs for robotic systems, AI software, infrastructure upgrades, and employee training. A comprehensive ROI analysis is crucial to determine the economic viability.

- Potential costs: Purchasing and installing robotic systems, developing and implementing AI algorithms, upgrading factory infrastructure, training employees, ongoing maintenance and repairs.

- Factors influencing ROI include production volume, labor costs (both current and projected), and the potential for increased efficiency and reduced waste. The potential for increased output and higher quality products needs to be carefully weighed against the significant initial investment.

Impact on Nike's Global Workforce

Automation inevitably raises concerns about job displacement. The potential loss of manufacturing jobs requires careful consideration of ethical implications and the development of strategies to mitigate negative impacts on Nike's workforce.

- Potential job displacement: Automation could lead to a reduction in labor needs in traditional assembly roles.

- Nike needs to invest in retraining and reskilling programs for affected workers, potentially transitioning them to roles in areas such as robotics maintenance, AI programming, and advanced quality control. The creation of new, higher-skilled jobs is crucial to balance the impact of automation.

Opportunities and Future Trends in Nike's Automation Strategy

Despite the challenges, automation presents significant opportunities for Nike to enhance efficiency, improve product quality, and implement sustainable manufacturing practices.

Advancements in Robotics and AI

Emerging technologies offer exciting potential for automating more complex aspects of sneaker production.

- Potential technologies: Collaborative robots (cobots) for assisting human workers, advanced vision systems for precise quality control, machine learning algorithms for predicting and preventing manufacturing defects.

- These advancements promise increased efficiency, improved product quality, and the capacity to handle more intricate designs and materials.

Sustainable Manufacturing Practices

Automation plays a vital role in promoting sustainable manufacturing.

- Sustainability benefits: Reduced waste through precise material usage, optimized energy consumption through efficient production processes, minimized environmental impact through improved resource utilization.

- Automation can contribute significantly to Nike's commitment to a more environmentally friendly supply chain, a key concern for environmentally conscious consumers.

Conclusion

Automating Nike's sneaker production process is a complex undertaking, fraught with technological hurdles, economic considerations, and social implications. Successfully navigating these complexities requires a strategic, phased approach that balances technological innovation with ethical considerations and a commitment to a sustainable future. The key takeaways include the need for adaptable robotics, advanced quality control systems, and strategies for workforce transition. Understanding the complexities of automating Nike's sneaker production process is crucial for the future of the industry. Continue your exploration of this fascinating topic by researching the latest advancements in robotic process automation for footwear manufacturing and the evolving role of AI in the supply chain.

Featured Posts

-

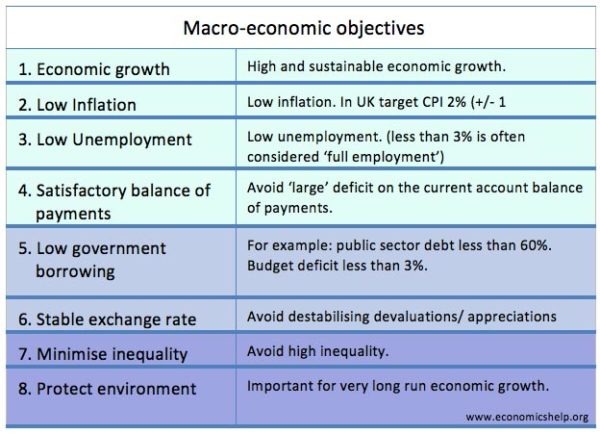

Unpacking Trumps Economic Goals Distributional Impacts

Apr 22, 2025

Unpacking Trumps Economic Goals Distributional Impacts

Apr 22, 2025 -

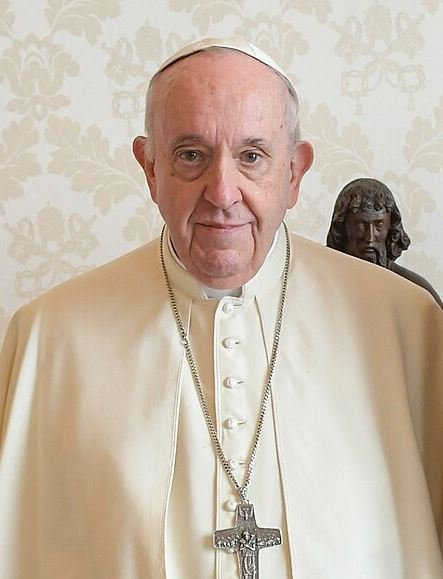

Understanding Papal Conclaves History Process And Secrecy

Apr 22, 2025

Understanding Papal Conclaves History Process And Secrecy

Apr 22, 2025 -

Technical Glitch Forces Blue Origin To Postpone Rocket Launch

Apr 22, 2025

Technical Glitch Forces Blue Origin To Postpone Rocket Launch

Apr 22, 2025 -

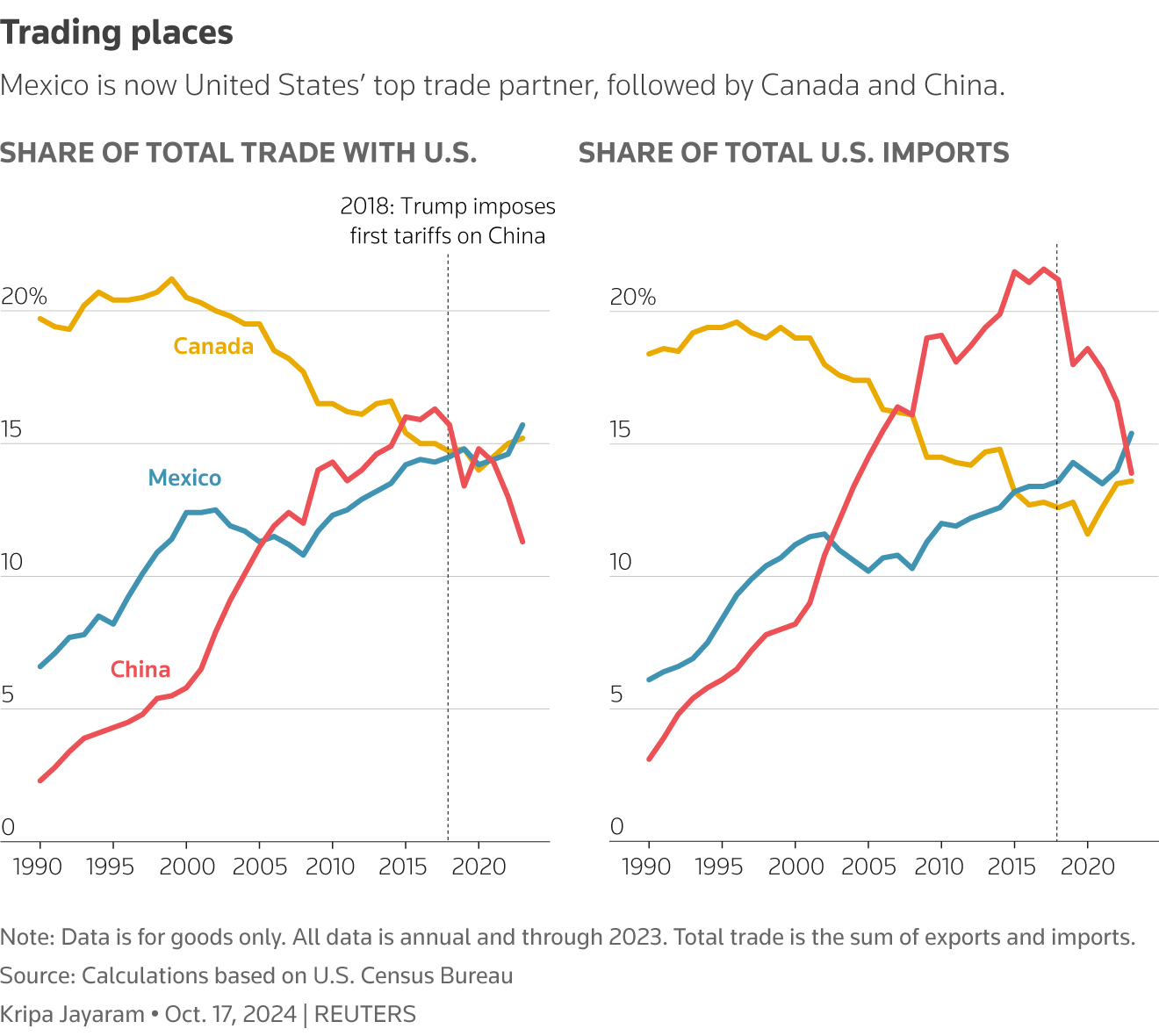

Tariffs And China The Impact On Export Driven Economy

Apr 22, 2025

Tariffs And China The Impact On Export Driven Economy

Apr 22, 2025 -

Navigate The Private Credit Boom 5 Dos And Don Ts

Apr 22, 2025

Navigate The Private Credit Boom 5 Dos And Don Ts

Apr 22, 2025