$70 Million Blow: Auto Carrier's Worst-Case Port Fee Scenario

Table of Contents

Understanding the Exploding Costs of Port Congestion

Port congestion is a major driver of increased port fees for auto carriers. Delays and extended dwell times directly translate into significantly higher expenses.

Delays and Dwell Times: The Primary Culprits

Extended dwell times – the time a vehicle spends at the port before being shipped or unloaded – are the primary culprits behind soaring port fees. These delays result in substantial charges:

- Demurrage: Charges levied for exceeding the free time allowed for unloading cargo from the vessel. These fees can easily reach hundreds of dollars per day, per vehicle.

- Detention: Charges assessed for holding containers or vehicles beyond the allotted free time at the terminal. Similar to demurrage, these fees can rapidly accumulate.

- Storage Fees: Additional charges for storing vehicles in port yards due to delays.

Several factors contribute to this congestion:

- Supply chain bottlenecks: Global supply chain disruptions continue to cause delays at ports worldwide.

- Labor shortages: A lack of dockworkers and other essential personnel contributes to processing delays.

- Infrastructure limitations: Inadequate port infrastructure, including limited capacity and outdated technology, exacerbates congestion.

Statistics show average dwell times have increased by X% in the last year, resulting in a Y% increase in associated port fees. This directly impacts the profitability of auto carriers.

The Impact of Rising Fuel Costs on Port Fees

Increased fuel costs significantly impact transportation expenses, adding to the overall burden of port fees. Higher fuel prices directly translate to:

- Increased trucking costs to and from the port.

- Higher costs for vessel operations, influencing the charges passed on to carriers.

Recent fuel price increases of Z% have already impacted the industry, pushing up port-related expenses. While alternative fuel options like LNG and biofuels are being explored, their widespread adoption and cost-effectiveness remain uncertain in the short term.

Analyzing the $70 Million Worst-Case Scenario for Auto Carriers

Let's dissect this alarming figure: a $70 million loss due to port fees represents a significant threat to the financial stability of auto carriers.

Dissecting the Calculation: A Breakdown of Fees

The $70 million figure is a composite of several significant cost components:

- Demurrage: A substantial portion of the total, potentially reaching tens of millions due to prolonged vessel delays and high daily charges.

- Storage: Millions in additional costs from storing vehicles in overcrowded port yards.

- Handling Fees: Expenses related to loading, unloading, and moving vehicles within the port.

[Insert chart or graph here visually representing the breakdown of costs across demurrage, storage, and handling fees.]

These high costs are particularly prevalent in specific ports and regions, where congestion is most severe, such as [mention specific ports or regions].

The Vulnerability of Just-in-Time Inventory Models

The reliance on just-in-time (JIT) inventory models significantly increases vulnerability to port fee increases and delays. JIT systems, while efficient under ideal conditions, offer little buffer against unexpected disruptions. Delays mean unsold vehicles sit at ports, accruing hefty fees.

Alternative inventory management strategies, including:

- Safety stock: Maintaining a small reserve of vehicles to mitigate the impact of delays.

- Improved forecasting: Using advanced analytics to predict potential disruptions and adjust inventory levels accordingly.

offer greater resilience against these financial shocks. Case studies demonstrate that companies relying heavily on JIT inventory suffered significantly greater losses during recent port congestion events.

Mitigation Strategies: Protecting Your Bottom Line

To navigate the challenges and protect your bottom line, implement the following strategies:

Negotiating Favorable Contracts with Ports and Shipping Lines

Strong negotiation skills are crucial in securing better rates and more flexible terms with port authorities and shipping lines. This includes:

- Developing long-term contracts that offer rate stability.

- Negotiating favorable free time allowances to minimize demurrage and detention charges.

- Building strong relationships with key stakeholders for proactive communication and problem-solving.

Optimizing Logistics and Supply Chain Management

Improving efficiency in transportation and warehousing is paramount. This involves:

- Streamlining processes to reduce dwell times.

- Utilizing technology, such as AI and predictive analytics, to forecast potential delays and optimize routes and schedules.

- Investing in advanced tracking systems for real-time visibility of cargo.

Insurance and Risk Management Planning

Comprehensive insurance coverage and thorough risk assessment are vital. Consider:

- Cargo insurance to cover losses from damage or delay.

- Business interruption insurance to mitigate financial losses from operational disruptions.

- Developing detailed contingency plans to address various scenarios.

Conclusion: Navigating the High Seas of Port Fees – Avoiding the $70 Million Blow

The high cost of port fees for auto carriers is a complex issue driven by port congestion, rising fuel costs, and reliance on just-in-time inventory models. Proactive strategies, including strong contract negotiation, optimized logistics, and robust risk management, are crucial for mitigating these costs and preventing devastating financial setbacks. Don't let escalating port fees sink your business. Implement effective strategies today to navigate the challenges and protect your bottom line. Learn more about mitigating your auto carrier's port fee risk [link to relevant resources].

Featured Posts

-

White House Cocaine Incident Secret Service Investigation Update

Apr 26, 2025

White House Cocaine Incident Secret Service Investigation Update

Apr 26, 2025 -

Following The Karen Read Case A Detailed Timeline Of Events

Apr 26, 2025

Following The Karen Read Case A Detailed Timeline Of Events

Apr 26, 2025 -

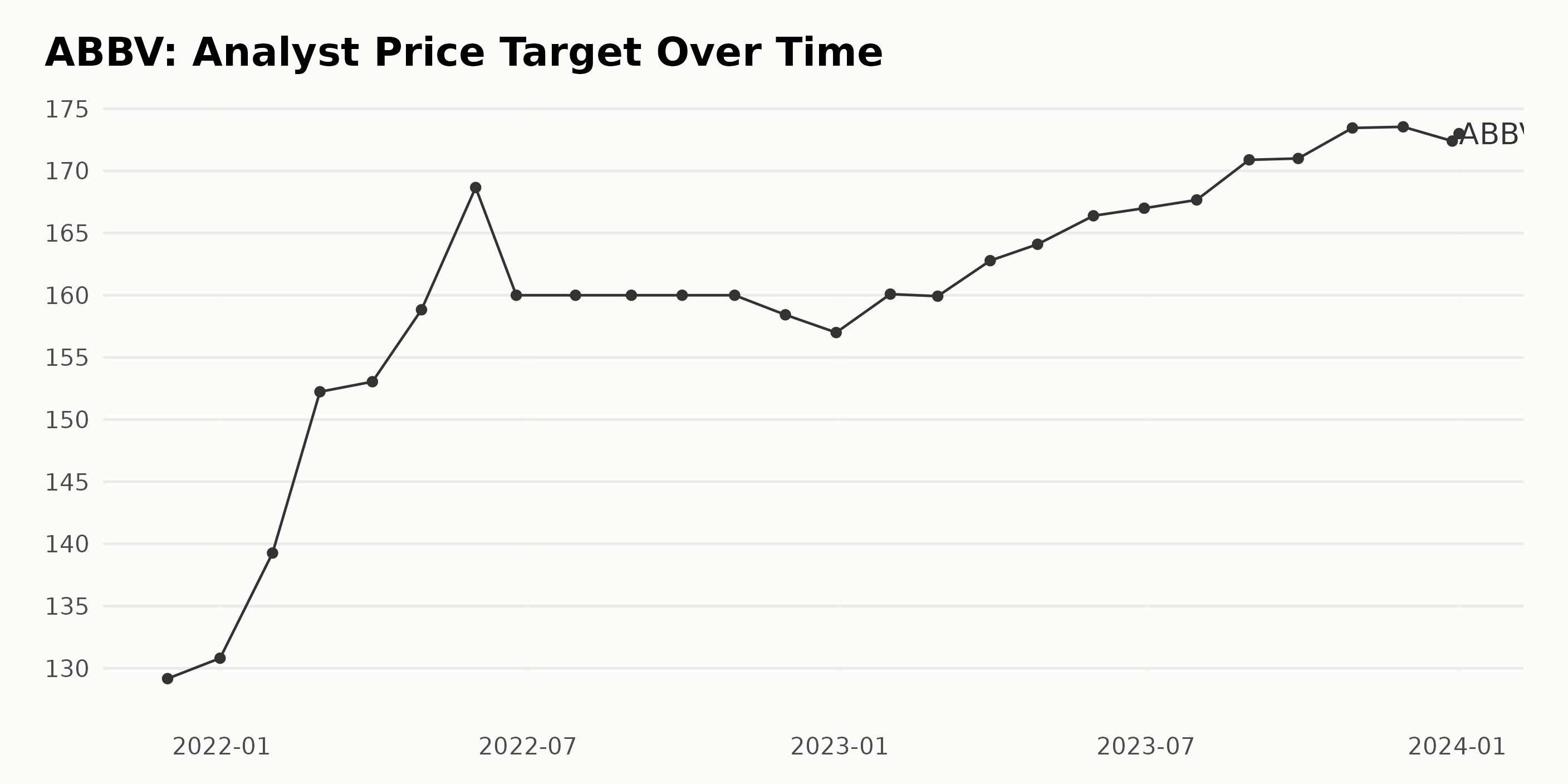

Abb Vie Abbv Stock Rises On Exceeded Sales Expectations And Increased Profit Forecast

Apr 26, 2025

Abb Vie Abbv Stock Rises On Exceeded Sales Expectations And Increased Profit Forecast

Apr 26, 2025 -

Auto Carrier Faces 70 Million Loss Due To Us Port Fee Increases

Apr 26, 2025

Auto Carrier Faces 70 Million Loss Due To Us Port Fee Increases

Apr 26, 2025 -

Thursday Night Football Nfl Draft First Round In Green Bay

Apr 26, 2025

Thursday Night Football Nfl Draft First Round In Green Bay

Apr 26, 2025