Why Nike Shoe Manufacturing Remains A Challenge For Robots

Table of Contents

The Complexity of Shoe Construction

The seemingly simple act of creating a Nike shoe belies a surprising level of intricacy. The challenges presented to robotic automation are significant, stemming from both the diverse materials and the precision required in the manufacturing process.

Varied Materials and Processes

Nike shoes incorporate a wide range of materials, from supple leather and durable synthetics to breathable textiles. Each material requires different handling techniques, posing a significant hurdle for robotic systems designed for uniformity. The manufacturing processes are equally diverse:

- Different stitching techniques: From simple straight stitching to complex patterns, the precision and adaptability needed to replicate various stitching techniques robotically are still underdeveloped.

- Varying material thicknesses and textures: Robots struggle to consistently handle materials with varying thicknesses and textures, leading to inconsistencies in stitching, gluing, and overall shoe quality.

- Intricate glue application requiring precision: The precise and controlled application of glue is crucial for a durable and aesthetically pleasing shoe. Current robots often lack the dexterity and control necessary for this task.

- Challenges of handling delicate materials without damage: Delicate materials like certain leathers or thin textiles require gentle handling to avoid damage. Robotic grippers often lack the sensitivity to avoid tearing or stretching these materials.

Dexterity and Precision Requirements

Creating a Nike shoe demands fine motor skills and extraordinary precision. Tasks such as threading laces, attaching intricate embellishments, and ensuring consistent stitching require a level of dexterity that surpasses the capabilities of current robotic technology.

- Limitations of current robotic grippers: Existing robotic grippers lack the adaptability and sensitivity to handle the wide variety of shapes, sizes, and textures of shoe components with the same proficiency as a human hand.

- Challenges in replicating human hand-eye coordination: The intricate coordination between hand and eye that humans possess is extremely difficult to replicate in robots. This impacts the precision and speed of many shoemaking processes.

- Inconsistencies in force application leading to damage or poor quality: Applying the correct amount of force during stitching, gluing, or other processes is critical. Inconsistent force application by robots can lead to damaged materials or a poorly constructed shoe.

Economic and Practical Considerations

Beyond the technical challenges, the economic viability of widespread robotic automation in Nike shoe manufacturing presents substantial obstacles.

High Initial Investment Costs

Implementing robotic systems in shoe manufacturing requires a substantial upfront investment. This includes not only the cost of purchasing advanced robotic arms and vision systems, but also the expenses associated with:

- Cost of advanced robotic arms, vision systems, and AI software: These technologies are expensive, representing a significant barrier to entry for many manufacturers.

- Expenses associated with training personnel: Skilled technicians are needed to program, maintain, and repair these complex systems.

- Potential downtime during implementation and maintenance: The process of integrating robotic systems into existing production lines can lead to disruptions and downtime, impacting production efficiency and profitability.

Return on Investment (ROI) Concerns

The financial viability of robotic automation hinges on factors like production volume, labor costs, and the potential for technological obsolescence. Currently, in many aspects of shoe manufacturing, the cost-effectiveness of human labor remains competitive:

- The need for high-volume production to justify the initial investment: The high cost of robotic systems means that large-scale production is necessary to achieve a positive return on investment.

- Comparison of labor costs vs. robotic operating costs: In regions with lower labor costs, the economic advantages of robotic automation might be less pronounced.

- Potential risks associated with rapid technological advancements: The rapid pace of technological change in robotics means that expensive systems can quickly become outdated, reducing their ROI.

Adaptability and Customization Challenges

Nike's success is partly due to its ability to adapt to changing trends and offer a wide range of designs and styles. This presents a challenge for robotic automation, which often struggles with flexibility and customization.

Handling Variations in Shoe Designs

Nike frequently introduces new shoe designs, requiring significant reprogramming and adjustments to robotic systems. This adaptability is currently limited:

- The time and cost associated with reprogramming robots for new designs: Reprogramming robots for each new design is time-consuming and expensive, limiting the economic feasibility of automation for smaller production runs or frequent design changes.

- The need for adaptable and flexible robotic systems capable of handling a wide range of shoe styles: The ideal robotic system would be capable of handling a wide range of shoe styles without requiring extensive reprogramming.

Meeting Consumer Demand for Customization

The growing trend of customized footwear further complicates the issue. Robots are currently not well-suited for highly personalized manufacturing:

- The need for robots with advanced sensory capabilities for customization: To handle customized orders, robots would need advanced sensory capabilities to accurately assess and adapt to individual customer specifications.

- Challenges in adapting mass production lines to personalized manufacturing: Current mass production lines are not designed for the flexibility needed to handle highly customized orders.

Conclusion

Automating Nike shoe manufacturing presents significant hurdles. The complexity of shoe construction, encompassing diverse materials and processes requiring precision and dexterity, remains a challenge. High initial investment costs, concerns about return on investment, and the need for adaptable systems capable of handling design variations and customization all contribute to the persistence of human labor in this industry. While advancements in robotics and AI show promise, fully automated Nike shoe manufacturing is not yet a reality. To learn more about the cutting-edge advancements potentially overcoming these obstacles, explore the latest research in flexible automation and AI-powered robotics – the future of Nike shoe manufacturing may depend on it.

Featured Posts

-

Circumventing Tariffs A Look At Tik Toks Influence

Apr 22, 2025

Circumventing Tariffs A Look At Tik Toks Influence

Apr 22, 2025 -

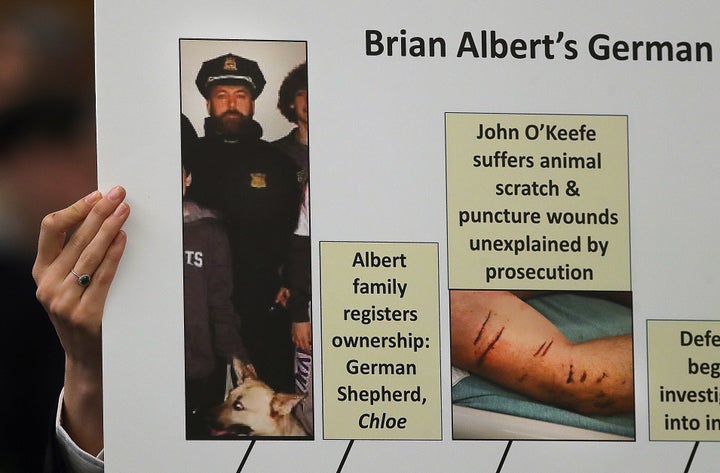

Karen Read Murder Trials A Complete Timeline

Apr 22, 2025

Karen Read Murder Trials A Complete Timeline

Apr 22, 2025 -

Ftc Probe Into Open Ai Examining Chat Gpts Data Practices And Privacy

Apr 22, 2025

Ftc Probe Into Open Ai Examining Chat Gpts Data Practices And Privacy

Apr 22, 2025 -

Building Voice Assistants Made Easy Open Ais 2024 Developer Announcements

Apr 22, 2025

Building Voice Assistants Made Easy Open Ais 2024 Developer Announcements

Apr 22, 2025 -

Middle Managers The Unsung Heroes Of A Thriving Workplace And Productive Teams

Apr 22, 2025

Middle Managers The Unsung Heroes Of A Thriving Workplace And Productive Teams

Apr 22, 2025