Robotic Limitations In Nike Sneaker Manufacturing: Challenges And Opportunities

Table of Contents

Dexterity and Precision Challenges in Complex Assembly

Sneaker assembly is a remarkably intricate process, far more complex than many realize. The creation of a single shoe involves numerous delicate steps that currently push the boundaries of robotic capabilities. Tasks such as precise glue application, the delicate stitching required on curved surfaces, and manipulating flexible materials like fabric and leather, remain significant hurdles for automation.

- Lack of fine motor skills: Robots, even the most advanced ones, still lack the fine motor skills and dexterity of human hands. The subtle adjustments and precision needed for many assembly steps are difficult for robots to replicate.

- Material variability: The properties of materials used in sneaker manufacturing can vary significantly, posing challenges for consistent robotic handling. Variations in thickness, texture, and flexibility require adaptability that current robotic systems often lack.

- Delicate component handling: Many sneaker components are delicate and easily damaged. Robots need to handle these parts with extreme care, preventing accidental tears, creases, or breakage – a challenge requiring advanced sensors and control systems.

- High error rates: In complex assembly steps, robotic error rates can still be relatively high compared to human workers. This leads to wasted materials, increased production time, and higher costs.

Cost and Return on Investment (ROI) of Robotic Integration

The integration of robotics into sneaker manufacturing is a significant investment. The high upfront costs of purchasing and installing robotic systems are just the beginning. Ongoing maintenance, programming, and potential downtime all contribute to the overall expense. A thorough assessment of the return on investment (ROI) is crucial before undertaking large-scale robotic integration.

- High upfront costs: Robotic systems, along with their specialized tooling and software, represent a substantial financial commitment.

- Ongoing maintenance and repairs: Robots require regular maintenance and occasional repairs, adding to the overall cost of ownership.

- Skilled technicians required: Programming, troubleshooting, and maintaining robotic systems necessitate skilled technicians, adding to labor costs.

- Potential production slowdowns: The initial implementation of robotic systems can sometimes lead to temporary slowdowns in production while workers adapt to new workflows.

- ROI comparison: A comprehensive cost-benefit analysis comparing robotic automation with traditional manufacturing methods is essential for determining feasibility.

Adaptability and Flexibility Issues in Diverse Production Lines

Nike's diverse product lines and frequent style changes pose a significant challenge for robotic automation. Each new sneaker design often requires reprogramming and retooling of robotic workstations, adding to costs and reducing flexibility.

- Adaptability to new designs: Current robotic systems often struggle to adapt quickly to new designs and materials, requiring significant reprogramming and potentially even hardware modifications.

- Time-consuming reprogramming: Reprogramming robots for each new sneaker model can be time-consuming and expensive, limiting the efficiency gains of automation.

- High cost of retooling: Adapting robotic workstations to handle different components or assembly processes frequently necessitates costly retooling.

- Need for flexible systems: The future of robotic automation in sneaker manufacturing depends on developing more flexible robotic systems capable of handling a wider range of tasks and adapting to diverse product lines.

Opportunities for Future Development and Collaboration

Despite the challenges, the future of robotics in Nike sneaker manufacturing is bright. Advancements in robotics, artificial intelligence, and collaborative robots offer exciting opportunities to overcome current limitations and enhance production efficiency.

- AI and Machine Learning: AI and machine learning can enhance robotic dexterity, precision, and adaptability, allowing for more complex and nuanced assembly tasks.

- Advanced robotic grippers: The development of more dexterous and adaptive robotic grippers is crucial for handling diverse materials and delicate components with greater precision.

- Collaborative Robots (Cobots): Cobots, designed to work alongside humans, offer the potential for seamless human-robot collaboration, combining the strengths of both.

- Improved sensor technology: Enhanced sensor technology can provide robots with more accurate feedback, improving precision and control during assembly.

- Automation of manual processes: Future advancements hold the promise of automating many currently manual processes, significantly improving efficiency and reducing costs.

Conclusion

While robotic limitations in Nike sneaker manufacturing currently pose significant challenges, the potential for future advancements is substantial. Overcoming these limitations through investment in research and development, particularly in areas like AI, cobots, and advanced sensors, will unlock significant opportunities for improved efficiency, reduced costs, and increased production flexibility. We encourage further research and development into innovative robotic solutions to address the challenges and fully realize the potential of automation in the footwear industry. The future of sneaker manufacturing may well be defined by the successful integration of advanced robotics, and we need to continue pushing the boundaries of this technology to achieve optimal results.

Featured Posts

-

Blue Origin Cancels Launch Vehicle Subsystem Malfunction

Apr 22, 2025

Blue Origin Cancels Launch Vehicle Subsystem Malfunction

Apr 22, 2025 -

The Next Pope How Franciss Legacy Will Shape The Conclave

Apr 22, 2025

The Next Pope How Franciss Legacy Will Shape The Conclave

Apr 22, 2025 -

Bof A Reassures Investors Why Current Market Valuations Are Not A Threat

Apr 22, 2025

Bof A Reassures Investors Why Current Market Valuations Are Not A Threat

Apr 22, 2025 -

Lab Owner Admits To Falsifying Covid 19 Test Results

Apr 22, 2025

Lab Owner Admits To Falsifying Covid 19 Test Results

Apr 22, 2025 -

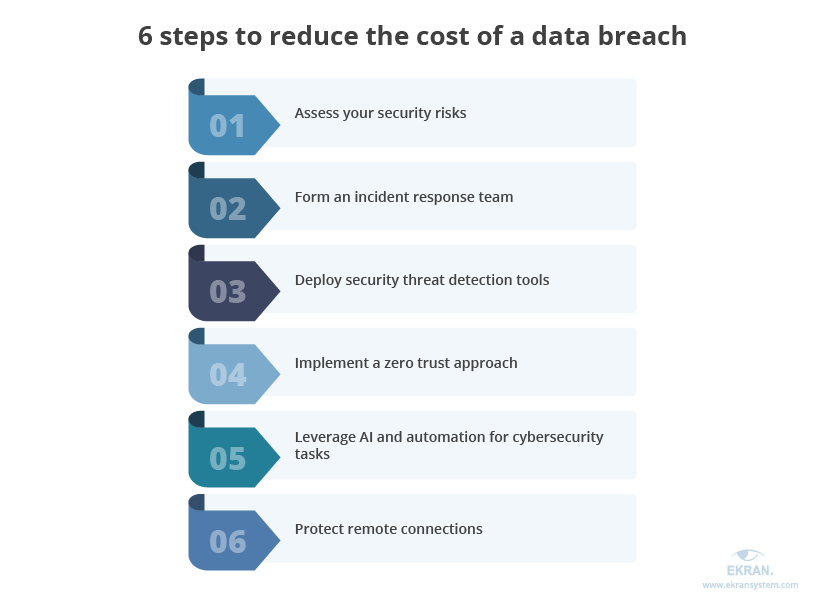

T Mobiles 16 Million Data Breach Fine Three Years Of Security Failures

Apr 22, 2025

T Mobiles 16 Million Data Breach Fine Three Years Of Security Failures

Apr 22, 2025